MARKETS

APPLICATIONS SERVICES

FROM THE CUSTOMER, TO THE COSTUMER

AUTOMOTIVE

High strength and low density, excellent surface quality and paintability also on-line, low tolerances and thermal dilatation, high thermal and chemical resistance, low investments.

C. VEHICLE

Highest rigidity of large parts without additional mechanical support, low investments (one tool – one piece), integration of different function and elements, excellent paintability and surface quality, low weight and complex possible shape

CONSTRUCTION

Effective alternative to traditional building materials due to their high strength-to-weight ratio, corrosion resistance, fire-retardant properties and design flexibility.

ELECTRICAL

Due to excellent insulation properties, high fire protection level, good mechanical and thermal resistivity and optimal cost.

ENERGY

High performance, cost-effective, sustainable solution for renewable energy applications. Long-term resistance coupled with extreme temperature tolerance and excellent electrical properties provide an ideal engineering solution for these new technologies.

INDUSTRIAL

High strength-to-weight ratio, chemical resistance, good mechanical properties and the capability to allow part-integration and design freedom

MASS TRANSPORT

Lightweight, high strength, thermal and chemical resistance, as well as offering fire-retardance and maintaining structural integrity in a fire situation.

SANITARY

Bath tubs and shower trays due to the combination of strength, stiffness and aesthetic appearance. Excellent thermal stability coupled with chemical resistance and durability for domestic appliance applications.

AUTOMOTIVE

menzolit® compounds for the Automotive industry

High strength and low density, excellent surface quality and paintability (also on-line), tight dimensional tolerances and low thermal dilatation, high thermal and chemical resistance, low investments – all these characteristics make SMC and BMC very attractive for the automotive industry. From body panels over structural parts to functional elements “under the bonnet” – all these parts can be realised with the wide range of Menzolit SMC and BMC products in fully automated, short cycle time, mass production processes.

AUTOMOTIVE PRODUCT DOWNLOAD

COMMERCIAL VEHICLE

menzolit® compounds for Commercial Vehicles

One of most well-known, highest volume applications of SMC is body panels for commercial vehicles. High rigidity of large parts without the need for additional mechanical support, low investment costs (one tool – one piece), integration of different functions and elements, excellent paintability and surface quality, low weight and complex shapes possible – these are the main advantages of SMC- making it an indispensable material for the truck and commercial vehicle industry.

COMMERCIAL VEHICLE PRODUCT DOWNLOAD

CONSTRUCTION

menzolit® compounds for Building & Construction

Menzolit’s SMC and BMC are formulated to offer an effective alternative to traditional building materials due to their high strength-to-weight ratio, corrosion resistance, fire-retardant properties and design flexibility. Such characteristics provide materials for use in a wide variety of applications including composite doors, water tanks, access chambers and manhole covers, where durability and long service-life are key requirements.

CONSTRUCTION PRODUCT DOWNLOAD

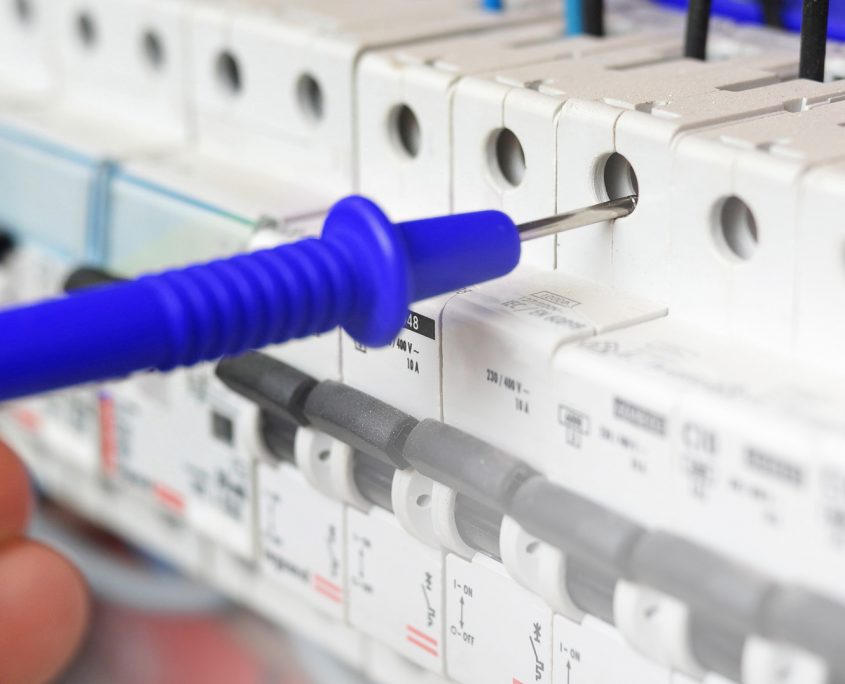

ELECTRICAL

menzolit® compounds for Electrical industry

The Electrical industry was the first and most traditional application field for SMC and BMC. Due to the excellent insulation properties, high fire protection level, good mechanical and thermal resistivity and optimal cost–performance ratio, these materials cover a large range of applications including electrical cabinets, lighting housings, low and medium voltage devices, etc. High productivity, with cycle times below 30 seconds and multi-cavity tools, guarantees low production costs and high quality of the final products.

ELECTRICAL PRODUCT DOWNLOAD

ENERGY

menzolit® compounds for the Renewable Energy market

Menzolit’s range of SMC and BMC composite materials provide a high performance, cost- effective, sustainable solution for renewable energy applications. Long-term resistance coupled with extreme temperature tolerance and excellent electrical properties provide an ideal engineering solution for these new technologies. Customised SMC and BMC formulations for static and dynamic components for both the distribution and control of energy are a significant opportunity for this fast developing industry.

ENERGY PRODUCT DOWNLOAD

INDUSTRIAL

menzolit® compounds for the Industrial market sector

With such extensive demands from the Industrial market sector the adaptability of SMC & BMC based composites compared to more traditional materials enables designers and specifiers to select the optimum product for a wide variety of applications. The benefits of high strength-to-weight ratio, chemical resistance, good mechanical properties and the capability to allow part-integration and design freedom are key to making SMC & BMC the materials of choice in the industrial market sector.

INDUSTRIAL PRODUCT DOWNLOAD

MASS TRANSPORT

menzolit® compounds for the Mass Transportation market

With the recognised benefits of lightweight, high strength, thermal and chemical resistance, as well as offering fire-retardance and maintaining structural integrity in a fire situation, SMC and BMC have long been the preferred choice in the mass transit market. Menzolit’s “Compounding Solutions” approach enables halogen-free materials to be developed to meet the demanding Fire, Smoke and Toxicity requirements of today’s rail and mass transit markets.

MASS TRANSPORT PRODUCT DOWNLOAD

SANITARY

menzolit® compounds for the Sanitary ware market

Menzolit supply a range of products for the particular requirements of the sanitary ware and domestic appliance markets. A growing trend is seen in the use of SMC in the manufacture of composite sinks, bath tubs and shower trays due to the combination of strength, stiffness and aesthetic appearance. Excellent thermal stability coupled with chemical resistance and durability make SMC and BMC the ideal material choice for domestic appliance applications.

SANITARY PRODUCT DOWNLOAD